Synthesis of p-Nitroacetanilide from Acetanilide

12 Sep 2015This is another lab report dug up from the archives of lab reports for the fun of it.

So, we got to do a nitration ages ago in organic chemistry labs, which was a whole bunch of fun. I had not nitrated anything in a long while when this chance arose, so it brought back some very, very fun memories. Now, this report has no yield or “after synth testing”, for reasons which will become apparent later.

Acetanilide can be nitrated using a mixture of nitric and sulphuric acids. The reasons for using sulphuric acid in the nitration of aromatic compounds is actually more interesting than I had previously thought, and I will be posting to explain that mechanism at a later date as it involves a great deal of diagrams, and I need to find another copy of Chemdraw as my by-hand drawing skills are a tad shite…

Anyways, on to the experimental/pictures part.

-

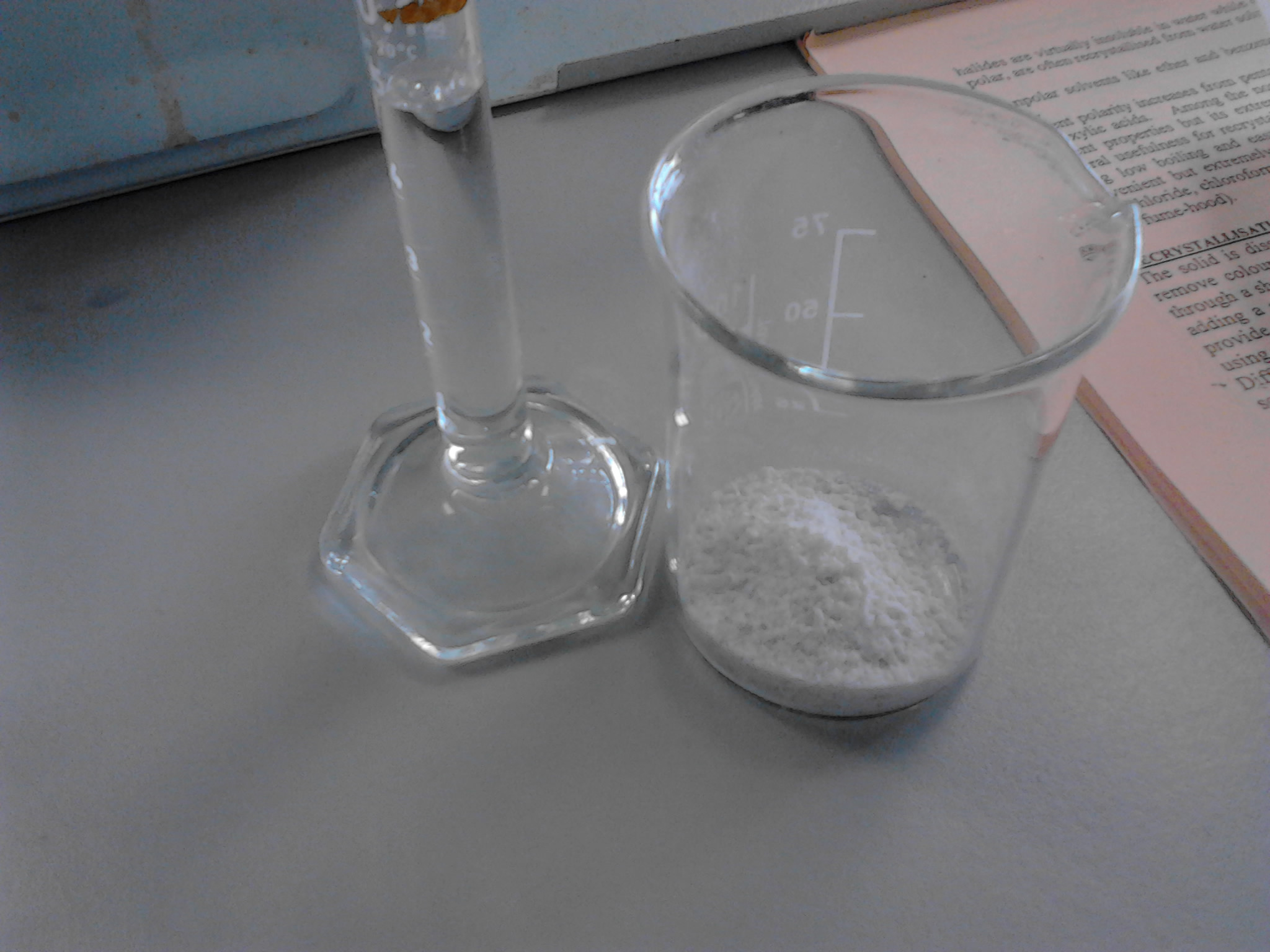

5 grams of acetanilide was weighed out, along with 5ml glacial acetic acid.

-

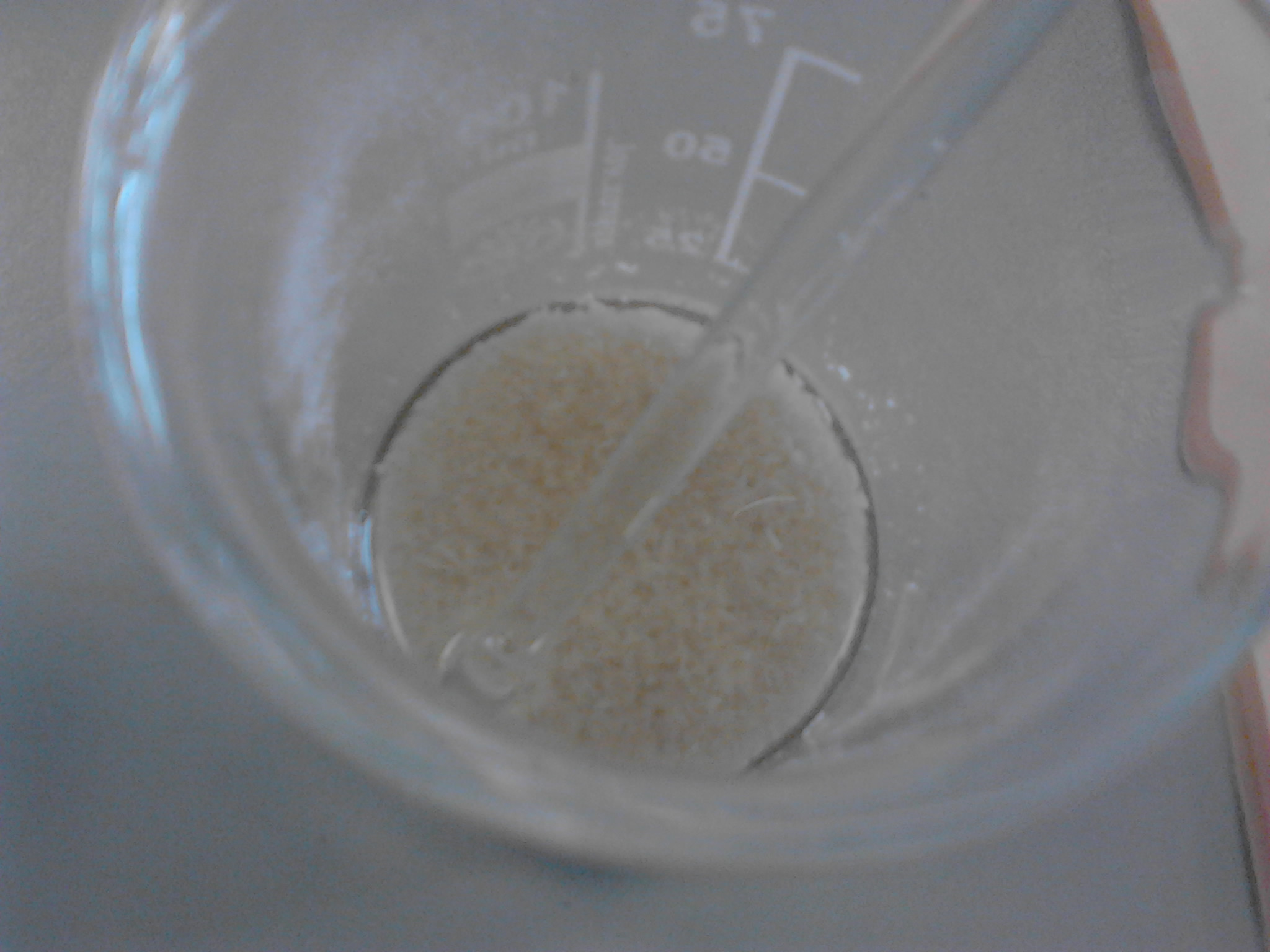

The acetanilide was dissolved in the glacial acetic acid in a 100ml beaker with a lot of stirring. It became a bit difficult to dissolve, so more stirring!

-

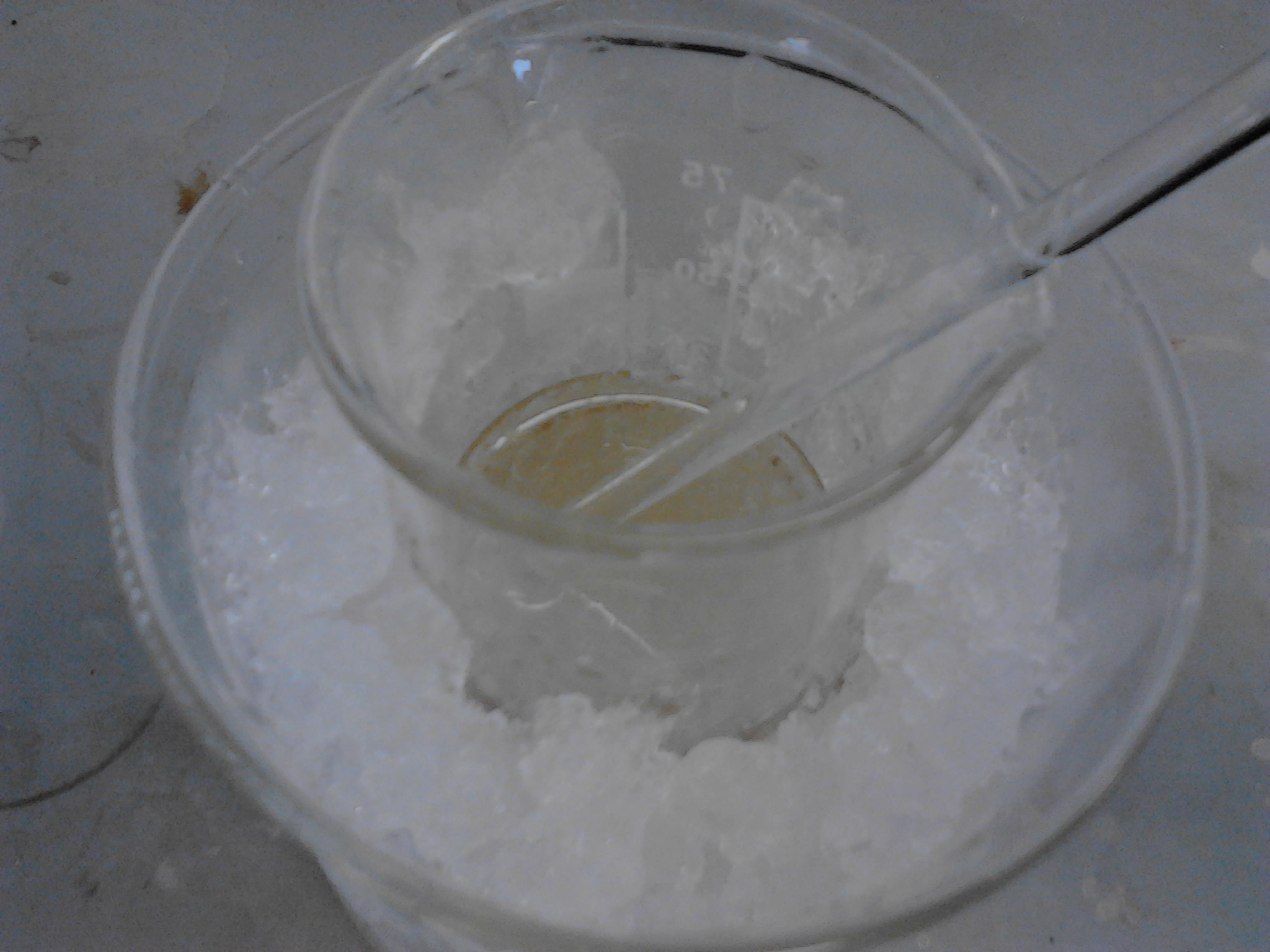

10ml of conc. sulphuric acid was added to this mixture with stirring and chilled in an ice bath. It became “gloopy”, about the consistency of polystyrene/petrol napalm, and heated up considerably. It also turned slightly yellow.

-

While stirring, and keeping the temperature below 25*C in the ice bath (which again, I had salted), 2ml of concentrated nitric acid was added dropwise. This took a good while to do.

-

The beaker was removed from the ice bath and allowed to stand for ~30 minutes unattended, in the fume hood.

-

The contents were dumped into ~50g of crushed ice, and the beaker rinsed with distilled water, the rinsings being added to the crushed ice mixture. This was stirred and a precipitate was observed.

-

The ice was let melt for 20 minutes, and the mixture was filtered using vaccum filtration. Water was poured through the funnel to wash the product.

-

Product was allowed to dry under vaccum for a while.

-

This is where the biggest cockup ever happened, so read closely. The product was meant to be recrystallized from methylated spirit/methanol. I sent my lab partner to procure this for me, and the guy just did not bother did not read the fucking label, and brought me a beaker of glacial acetic acid. My nose being ruined by this point, I did not discern the smell.Anyway, the product was dissolved, with great difficulty, using heating. The funny part happened during this. Becoming frustrated with the slow progress of dissolution, I decided to use a magnetic stirring hotplate. At this point, I did not know I had been given glacial acetic acid as opposed to Methanol.

So, onto the hotplate it goes, turn the stirrer up to eleven, and stand back. Moments later, a “cloud” of “acetic acid gas” (you know, STRONG vinegar fumes) evolved, punching my partner straight in the eyes and throat with the smell of a thousand chip shops.

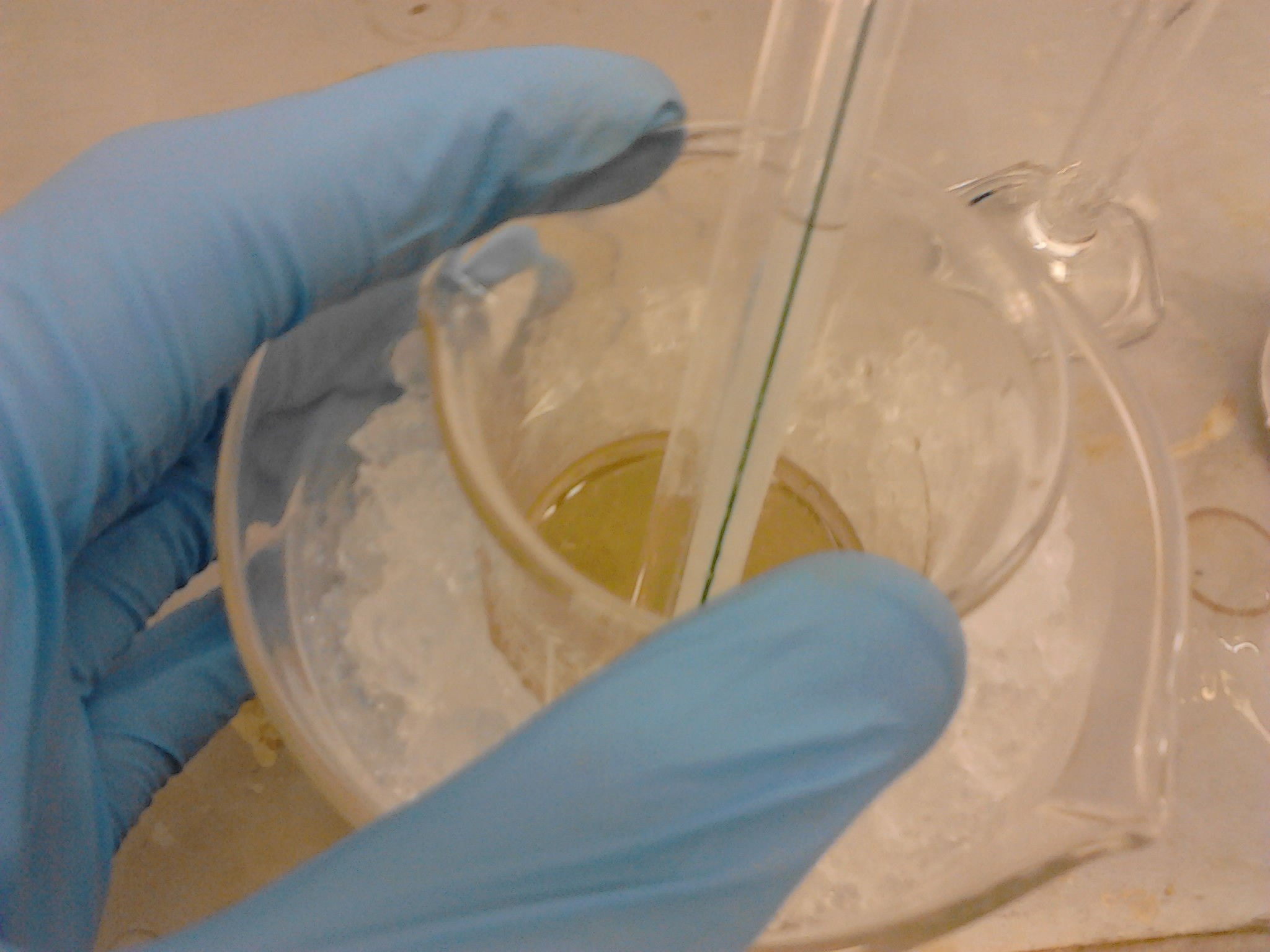

The solution was let sit in an ice bath then, trying to recover a product. Less than 200mg was recovered, however the lab demonstrator told me the crystals recovered would be of incredibly high purity due to the “unusual” recrystallization performed. Simply due to a time constraint, I never got to put the sample on the FT-IR machine, which was a major disappointment as I enjoy using that piece of hardware!

Photo: Dissolving.

Photo: Attempting Recovery.

Results

I need a new lab partner, my current unit is defective. I was also at fault for failing to check. Still though, we got what LOOKED to be a clean product out.

Conclusions:

Never trust a lab partner, always double check things. Even if you have an excellent working relationship, double fucking check.

Anyway, provided you don’t bollox it up like we did, this is a pretty simple way to manufacture p-nitroacetanilide and a solid introduction to nitration reactions.